Anova is now providing Temperature Mapping resources to our clients. This service allows us to further assist our research and development clientele with their commissioning process to validate the performance of their temperature-controlled spaces and help prove compliance with the FDA’s GMP requirements.

What is Temperature Mapping?

rending temperature and humidity over time within a space to a very high degree of accuracy (+-0.1C). The purpose of temperature mapping is to ensure that specific storage or process area is at the required temperature. The results provide a temperature map defining cold or warm spots within the tested space.

Per the FDA, temperature mapping is mandatory for any spaces where medicines, vaccines, temperature-sensitive products, or biological samples are stored. Temperature mapping surveys provide validated insights to support informed decisions regarding the most appropriate monitoring solutions to safeguard pharmaceutical materials correctly.

Protecting Your Assets

Anova offers comprehensive support and information by defining a temperature mapping program to fit your specific storage and regulatory needs. We will provide a full, on-site automated solution for mapping temperature circuits by using Vaisala Temperature Data Loggers. The data loggers give highly accurate, stable, and reliable measurements, ensuring tamper-proof files and electronic records that meet 21 CFR Part 11 requirements.

The devices can be used in any space but are primarily used by pharmaceutical GMP applications to determine if a storage area can maintain a temperature within defined limits such as refrigerators, freezers, warehouses, incubators, and cold rooms in regulated environments. In conventional buildings, we can use temperature mapping to troubleshoot common HVAC issues, such as condensation, or poor temperature control. Lastly, we can use temperature mapping to verify or demonstrate the functionality of HVAC systems as part of the commissioning process.

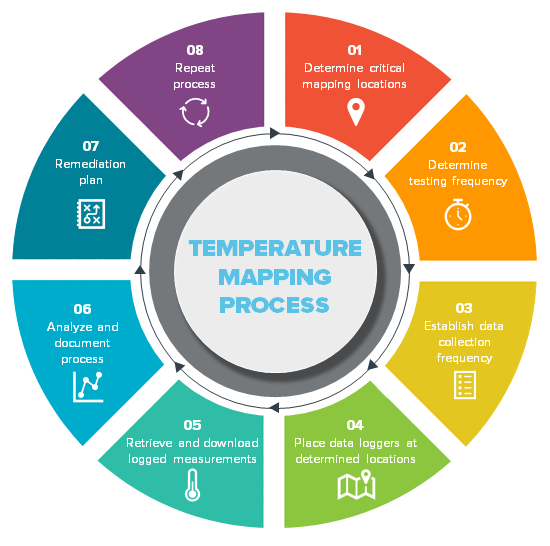

Temperature Mapping Process

The type of space or unit being tested, as well as user requirements, will determine the number of loggers used, placement, and duration. For example, in a warehouse, you would need to consider the size of the warehouse, racking and shelving, windows or skylights, and locations of ductwork and diffusers. Distributing loggers throughout the testing area will provide a detailed understanding of the performance of the space.

The testing area drives mapping duration. For a refrigerator or freezer, the typical mapping time is 24-72 hours, whereas the period for a warehouse might be as long as seven days.

In general, Anova uses the “ISPE Good Practice Guide: Controlled Temperature Chamber Mapping and Monitoring” for testing strategies.

Once the mapping phase is complete, we remove and connect the loggers to a validated software program that downloads and presents environmental data in compliance with global regulations and standards.

Reporting

After the temperature mapping program, our engineers will remove the temperature loggers and download the data to create an inclusive Temperature Mapping Report. We will create a full report that includes information on humidity and hot and cold spots, analysis of recorded data, and remediation recommendations.

Temperature Mapping Benefits

Temperature mapping can reveal vital information about the performance of your building or equipment, which can validate proper operation or identify and resolve any deficiencies. Temperature mapping offers several benefits, including:

- Reveal locations of any humidity and hot and cold spots, chilling/heating system variances, or power outages

- Temperature recovery from environmental effects such as opening doors or the presence of personnel

- Document data of the environmental conditions and performance of your product storage spaces and equipment

- A cost-effective way to monitor and ensure the performance of your temperature-controlled areas comply with the FDA’s GMP requirements

- A full report detailing information on humidity and hot and cold spots, analysis of recorded data, and remediation recommendations

If you are interested in temperature mapping for your facility or would like additional information, please contact Lawrence Kong.